|

MetalFirstAid

49 years of welding, engineering and construction experience.

34 years of aluminium welding experience.

Experienced, proficient,

onsite mobile welder.

Solving all your

welding problems

|

Deon van Rooyen

Specialist

Aliminum welder

Iron Man

Metal First Aid

|

Mob: 07745 775 212

Tel: 0333 666 3213

eMail:

Deon@

AllMetalWeldingServices.co.uk

I very seldom go out to a client to look at their welding requirements.

My approach to work is

"nothing is a problem"

|

Mobile welder. Welding near me. Welders near me.

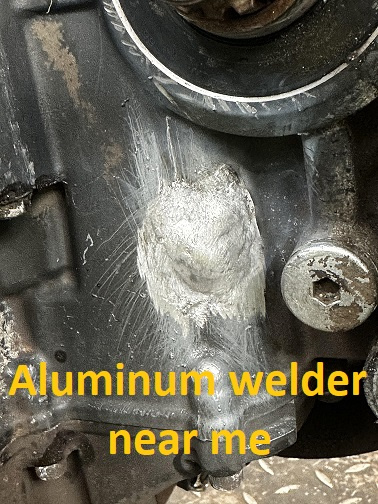

Motorcycle Accident Aluminium Welding Repairs

Aluminium welding experience on Porsche, Ferrari, Lamborgini, Bugatti Veyron, Audi R8, Mercedes, BMW, Land Rover.....plus all other makes of cars.

Motorcycle accident aluminium welding repairs London and surrounding areas. Looking for an aluminium mobile welder near me, welding near me, welders near me or mobile welders near me? Message me or give me call.

Drop me a photo plus your address and I'll send you a quote.

Here are just a few of the many examples of aluminium welding repairs I have done over the years. I have a habbit of forgetting to take photos after I finish the work. Not intelegent :)

I offer a mobile welding service. Looking for an aluminium welder near me, or welder services? Mobile welders come to you.

|

|

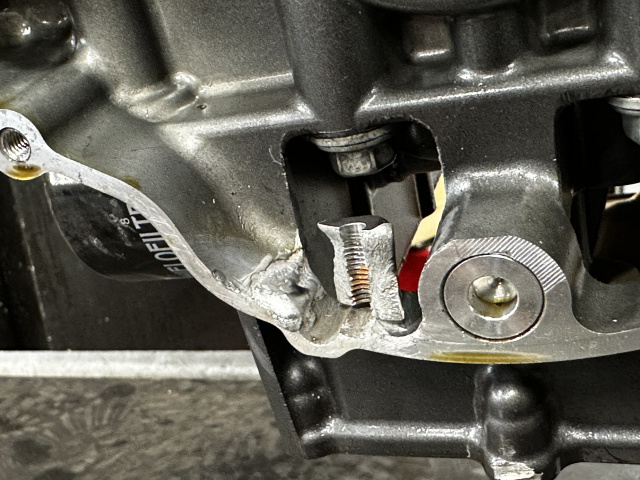

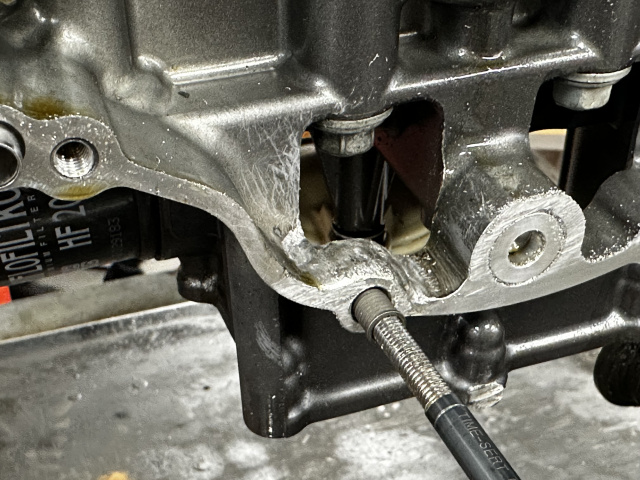

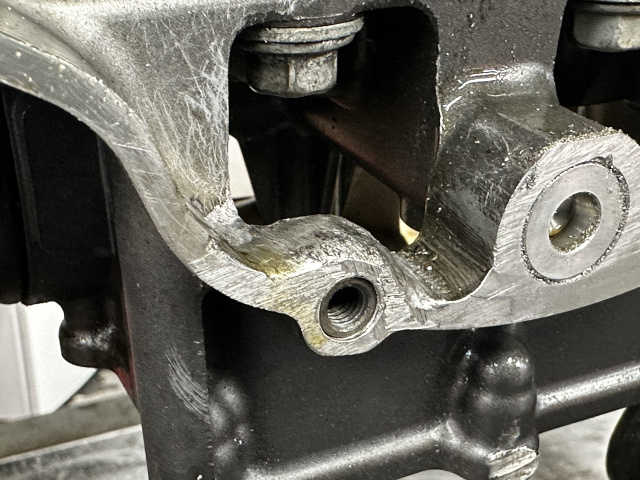

MotorCycle accident aluminium welding repairs

The aluminium engine casing on this motorcycle broke on impact in an accident. You can see the piece that broke out. I purposely did not aluminium weld the broken piece back in place, but instead built up the area with solid aluminum welding.

Far stronger doing it this way.

|

|

Welding aluminium is the most difficult of all welding methods but, it is my favorite.

I then repaired/inserted a thread insert in the casing which turned out perfect.

Once completing the TIG aluminium welding I ground it flat, plus I ran a metal file over the gasket surface to make sure everything was nice a true for the gasket to seal onto.

|

|

|

The drilling was easy enough by using the old thread as a guide as to where to drill for the thread insert installation.

The metal thread insert ends up far stronger than the original aluminium thread.

I asked, and the cusomer said he searched "Aluminium welder near me" and "aluminum welding near me" to find me on a Google search.

|

|

Offering mobile aluminum welding repair services. Aluminum welding repairs to engine casings. Aluminium welding repairs to any components. Looking for aluminum welders near me or aluminium welding near me? Then get in touch for me to help solve your problems for you.

Motorcycle mobile welding services, coving a 20 mile radius from west London

(no traveling fees) Traveling fees added, if further than 20 miles from Hammersmith.

|

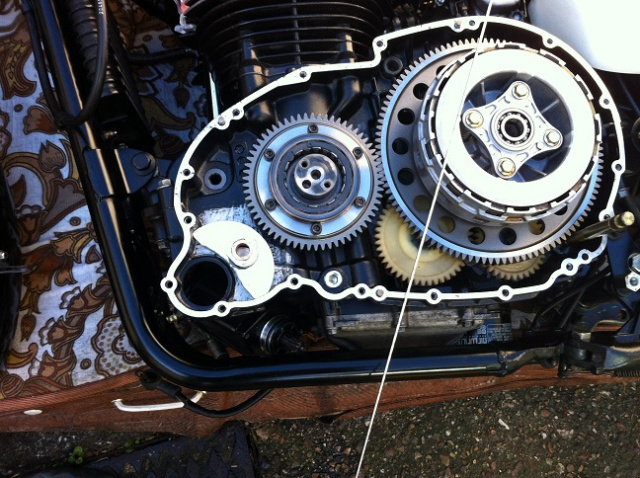

Motorcycle aluminum welding repairs

|

|

This is a common problem where the chain comes off and smashes the engine casing.

Fortunately this only broke off the sprocket cover bracket but ended up tearing out a piece of the casing. Normally the chain smashes through the engine casings which is a big headace.

|

|

|

I cleaned up the aluminium surface to be welded.

There wasn't enough room to get in with my TIG welding torch to weld the support bracket back in place and be certain there would not be any oil leaks, so my approach was to weld the hole closed first.

|

|

|

The aluminium welder I used here is called a Stealth welding machine. 200 amp AC/DC machine. Recently upgraded my old machine to this aluminium welder. Works like a dream in comparison to the old aluminium welder.

This aluminum weld turned out perfect without having to grind it at all. Turned out nice and smooth. |

|

|

|

This is the sprocket cover support bracket that broke off. As mentioned before, I decided not to weld it back in place as the access space was limited.

I had to cut it shorter to compensate for the weld that I had finished on the casing. The mechanic helped to hold it in place to get it all aligned.

|

|

|

All nice and strong and perfectly aligned.

I was really pleased with my choice of approach not to try and weld the broken out piece back in place. It was too risky trying to get access deep inside that cavity. Too restrictive and may have ended up with an oil leak.

|

|

|

All lined up perfectly.

Another happy new regular cutomer.

Building up a reputation for myself around London as an aluminium welder.

|

Broken motorcycle exhaust stud repair

1.

This is a Yamaha 1000.

Customer tried removing the old exhaust stud and snapped a piece off the aluminium on the head.

I had to carefully TIG aluminium weld around the threaded area, building it back up again to bring it back to the original shape.

2.

Aluminium welding is really tricky. Not to overdo the welding but necessary to get just the right temperature for maximum penetration and strength.

Aluminium TIG welding runs at 660°C.

3.

Once I finished all the aluminium welding, I ground the edges smooth and faced off the surface where the thread insert was going to be installed. I still had a hole where the old thread was visible, so I used that as my guide to drill and install the thread insert. Turned out really well. Stronger than the original aluminium thread.

The cusomer searched for "Aluminium welders near me" to find me on a Google search.

I am always interested and ask my customers how they found me. Most searches used are "Aluminium welding near me" "Welder services near me" and "Welding service near me"

I create my own websites and apply all the SEO myself. Something I have learned over the years. I find it very mentally stimulating and interesting.

Suzuki Aluminium Engine Casing Welding Repair

It is really difficult and time consuming repairing/welding over an old welding repair, but obviously can be done.

A Suzuki motorcycle agent in Leitchworth asked me to take a look at doing an aluminium engine casing welding repair for them. The chain had come off and smashed the engine casing.

The casing had an aluminium welding attempt before by another aluminium welder.

Hence the brown epoxy shown in the picture attempting to trying and stop the oil leak by the previous owner.

I had to remove all traces of the epoxy before welding.

This shows my results welding aluminium over the old previous attempt from another aluminium welder. To get rid of all impurities and pitted cavities as-well-as working the oil out of the cavities too.

The weld here is not very neat because I had to repair over someone else's previous attempt and had to repair over the old contaminated welds.

Left, showing the TIG aluminium welding machine I use to do the aluminium welding repairs with.

This was one of the most difficult repairs welding aluminium I've done.

Repairing over the old aluminum welding meant a lot more welding had to be done, causing considerable heat input, which meant, the casing contracted slightly. Causing a bow/distortion on the sump gasket surface/casing.

To fix that, I had to weld/build up, onto the gasket surface to build up the gap caused by the shrinkage/distortion from the heat of the welding.

Welding aluminium is one of the most difficult of all welding methods.

I then had to carefully file down the weld to get a perfectly flat and true surface for the sump gasket to seal onto.

The weld here is not very neat because I had to repair over someone else's previous attempt and had to repair over the old contaminated welding.

Fantastic phone call a week later

I was very please to get a phone call from this client, AM-Suzuki.co.uk agent in Letchworth, saying how happy they were after extensive testing running the engine on numerous runs to find no oil leaks.

I suggested they use 2 gaskets to seal the sump, but they only used one.

Very pleased with the results

I asked, and the cusomer said he searched "Aluminum welder near me" and "mobile aluminium welding near me" to find me on a Google search.

Yamaha R1 Aluminium Engine Casing Welding Repair

Image to the left showing the damage to the aluminium engine casing.

Threads broken out and the aluminium casing was cracked too.

TIG aluminium welding used to repair this casing plus threads welded closed.

Casing filed down and holes drilled out in possition, ready for the new M6 thread inserts to be installed.

This is a close-up shot showing the M6 thread inserts installed.

Thread Insert/Repair

These thread repair inserts are amazing. The threads end up stronger than before after the repair.

They are super thin inserts, so you don't end up loosing strength after drilling out the casing before installation.

Another successful repair.

Welding aluminium

Another happy customer

This is a repair to a clutch bracket on a motor cycle.

I can't remeber the type of motorcycle. The bike was dropped and the replacement part was over £600. This repair came to £110 plus postage. (13/06/2010)

Successful repair, once again.

I find welding aluminium so satifying. My favourite out of all the welding methods.

Triumph motorcycle

Aluminium engine casing welding repair

This was a starter motor casing

that needed an aluminium welding repair

The customer made all the componenets. All I did was pitch up. Welding aluminium was the easy part for me.

The aluminium welding turned out perfect

|

Disclaimer:

I cannot guarantee a successful weld. Every type of aluminium product is different, which means different results.

I cannot be held liable in the event of there being damage caused to your item through the welding repair process.

I can also not be held liable in the unfortunate event of a breakage occurring to your item causing damage or harm to anyone or anything else due to structural or weld failure.

Aluminium welding temperature reaches 660oC, so all paint work will be destroyed around the welded area in the process. There may also be damage caused to seals or other components due to the excessive heat from the weld.

But, saying that, I have an incredible track record of successful welds. As my poster reads below, I make a point of making my welds stronger than the original.

|

Mobile aluminium welding repair services. Motorcycle aluminium welding repairs. Aluminium welding repairs to engine casings. Aluminium welding repairs to any components.

Motorcycle mobile welding services, coving a 20 mile radius from west London

(no traveling fees) Traveling fees added, if further than 20 miles from Hammersmith

|

|

Qualified Coded Welder

Pipe and Structural

Coded Welder

13 CM5JIC SUMMIT SKILLS

Welding Test Level 3

500/4746/2

L/501/9430

|

____________________________

49 years of welding, engineering and construction experience.

34 years of aluminium welding experience.

Reliable and friendly, mobile onsite coded welding services

in London and surrounding areas.

Contact:

Deon van Rooyen

Tel: 0333 666 3213

Mob: 07745 775 212

eMail:

Deon@AllMetalWeldingServices.co.uk

_____________________________

Prompt, Accurate, Affordable & Friendly Welding Service

Servicing London, plus surounding areas

MetalFirstAid

|

Higos Insurance Services Ltd - Public Liability Insurance

__________________________

Public Liability : £2,000,000

Insurance cover under -

Deon van Rooyen t/a

All Metal Welding Services

|

We have full public liability insurance cover

The importance of using a company with the correct insurance cover.

Policy no. 10771543

______________________________

|

|

Coming soon!

I have been teaching one-on-one welding courses since 2010 with an amazing 97% success rate.

But, now I'm in the process of creating video welder training courses. The video courses will be far more beneficial in comparison to the one-on-one training.

I am reaching retirement and want to pass on all my accumulated knowledge to as many people as possible. It is a skill for life.

Weld in 1 Day™

|

To enhance your user experience on our website, this site uses cookies.

If you continue to browse, you accept the use of cookies on our site.

See our Privacy Policy

for more information.

To enhance your user experience on our website, this site uses cookies.

If you continue to browse, you accept the use of cookies on our site.

See our Privacy Policy

for more information.